ADDITIVE MANUFACTURING

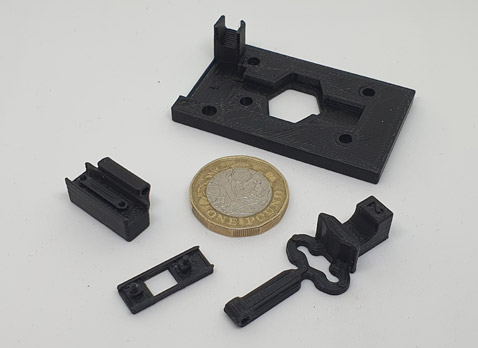

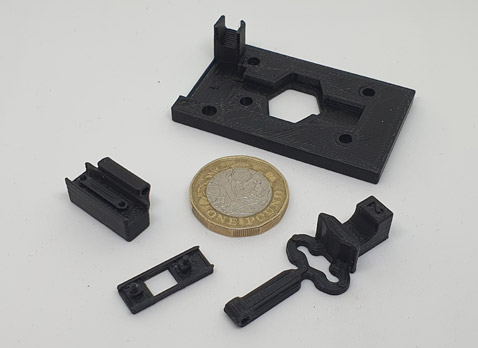

3D Printing Service

We have inhouse FDM and SLA 3d printing capabilities with large capacity high accuracy machines.

We have capacity to produces parts up to 400mm (X)x 400mm (Y) x 650mm (Z) with Dimensional accuracy +/-0.1mm

We Specialize in:

- 1 off prototypes

- Small batch production

- 3D Printed Tooling

- Machining fixtures

- Assembly fixtures

- Tooling

We can not only print but help design your Parts and provide a full design and manufacture service for custom Machine & Assembly fixtures and Tooling

Materials:

Carbon Fibre Reinforced Nylon,

Carbon Fibre Reinforced Nylon is ideal for anyone that desires industrial structural components with high modulus, improved chemical and thermal resistance, excellent surface quality.

Material Characteristics:

- High Strength,

- High Modulus Carbon Fiber – excellent stiffness

- Good Toughness,

- Wear Resisting,

- High Temperature resistance (up to 196°C)

- Good flame resistance, Flame-retardant level: UL94-V2

Suggested Applications:

- 3D Printed industrial parts

- Machining fixtures

- Assembly fixtures

- Tooling

- Under the hood automotive

- High performance parts

PETG,

PETG is a Glycol Modified version of Polyethylene Terephthalate (PET)

It is a semi-rigid material with good impact resistance, but it has a slightly softer surface which makes it prone to wear. The material also benefits from great thermal characteristics.

It’s an excellent filament choice for printing objects that need to be sturdy, have a smooth surface

Material Characteristics:

- Durable and tough.

- Good chemical / water resistance.

- High impact strength.

TPU/ TPE,

TPU/ TPE,

thermoplastic polyurethane (TPU/TPE) material

Material Characteristics:

- Shore Hardness = 85A to 95A

- Truly flexible (no fill or layer manipulation required to achieve performance)

- 660% elongation allows for repeated movement and impact without wear or cracking

- Polyurethane composition allows for excellent vibration reduction

- Abrasion resistance 20% better than ABS and 68% better than PLA

- Chemical resistant to many materials, including naphtha, ASTM Oils #1-3, petroleum and freon

- REACH and RoHS 2002/95/EC Directive compliant

Suggested Applications:

- Seals,

- Gaskets,

- Plugs,

- Leveling Feet,

- Protective Applications

PLA,

PLA,

Polylactic Acid, commonly known as PLA is one of the most popular materials used in desktop 3D printing

Pros

- Low Cost

- Stiff and good strength

- Good dimensional accuracy

- very good aesthetics

- Good shelf life

- Lots of Colours

Cons

- Low heat resistance

- Brittle

- Not suitable for outdoors (sunlight exposure)

TPU/ TPE,

TPU/ TPE, PLA,

PLA,